FCE Gomma Srl

"During the years we have performed countless projects and responded to many needs, but still today we notice the amazement of some customers to find out how many and what capabilities can guarantee the use of a so simple substance but at the same time flexible, adaptable and resistant. We believe that still so much to say about the rubber and that is what we try to do every day, to the best."

A. Restelli

FROM IDEA TO PRODUCT

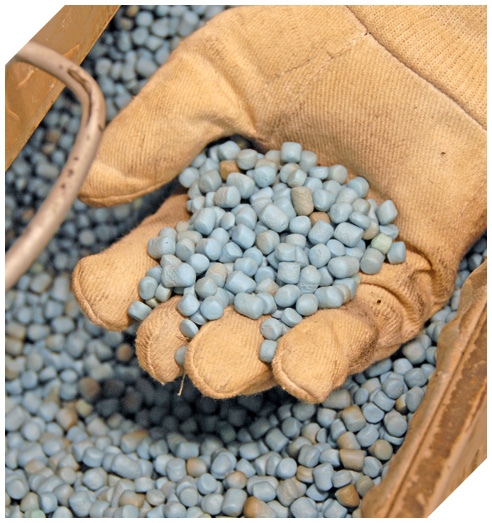

MATERIALS

Elastomers and special rubberFCE Gomma Srl transforms all types of synthetic and natural mixtures, starting from silicone polymers to organic and polyurethane ones.

COMPOUND DEPARTMENT

INNOVATIVE FORMULASThanks to the compound department, FCE Gomma Srl has been able over the years to develop its formulas with the collaboration of the most qualified international suppliers of raw materials.

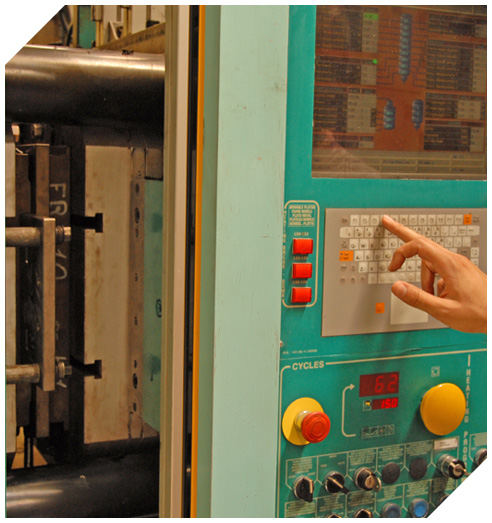

MOLDING

Molded rubber productsThe company has many years of experience in systems of compression molding, injection molding, transfer and cold runner systems.

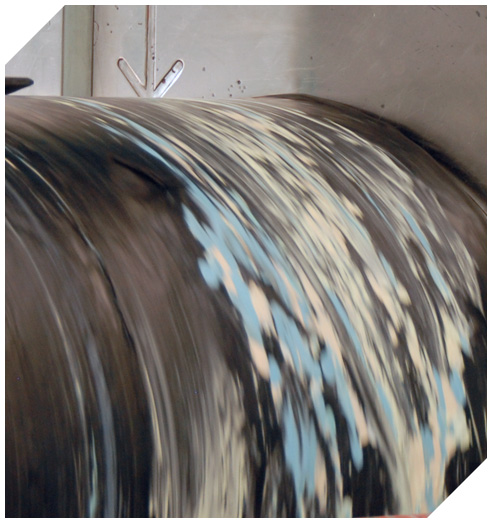

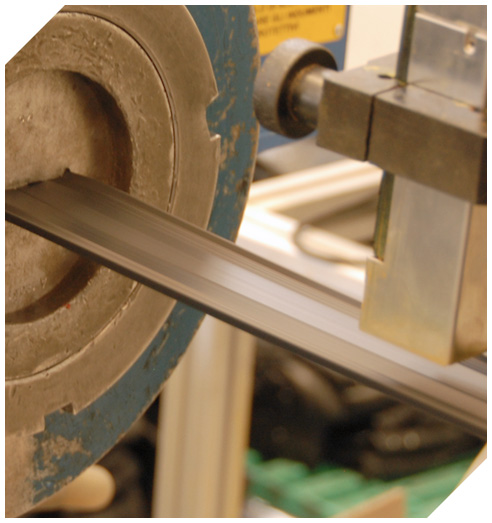

EXTRUSION

Extruded items in rubberThe machine park is completed by an extrusion line dedicated to the silicone and two lines for organic materials such as EPDM, NBR and CR also as co-extruded for different colors, different hardness or solid rubber and sponge rubber combinations.

COMPANY

The quality and reliability of FCE Gomma Srl, also favored by the excellent geographical location in just 20 kilometers from the Swiss border, has allowed the company to develop more than 50% of its business abroad, mainly in German speaking countries

ExplanationSUSTAINABILITY

FCE Gomma Srl monitors, verifies and constantly corrects the energy consumption indicators, waste and emissions into the environment with the aim of achieving a continuous improvement.

ExplanationQUALITY

FCE Gomma Srl produces high precision rubber with guaranteed quality and traceability of the entire production cycle. The control of the finishing process allows operating also in areas with Zero Defects formula request.

ExplanationLAST NEWS

CONTACT

-

Headquarter

Via Magistri Comacini, 8 - 22078 - Turate (Co) - IT

Tel +39 02 9675 1661 - Fax. +39 02 96751663

P.iva IT02011320138 - REA Como233981

Cap. Soc. 40.000 EUR I.V. -

Storage

Via dell'artigianato, 5 - 22078 - Turate (Co) - IT

Orari: 08.00/12.00 - 13:30/17:30 - Code of conduct - Privacy Policy - Cookie Policy